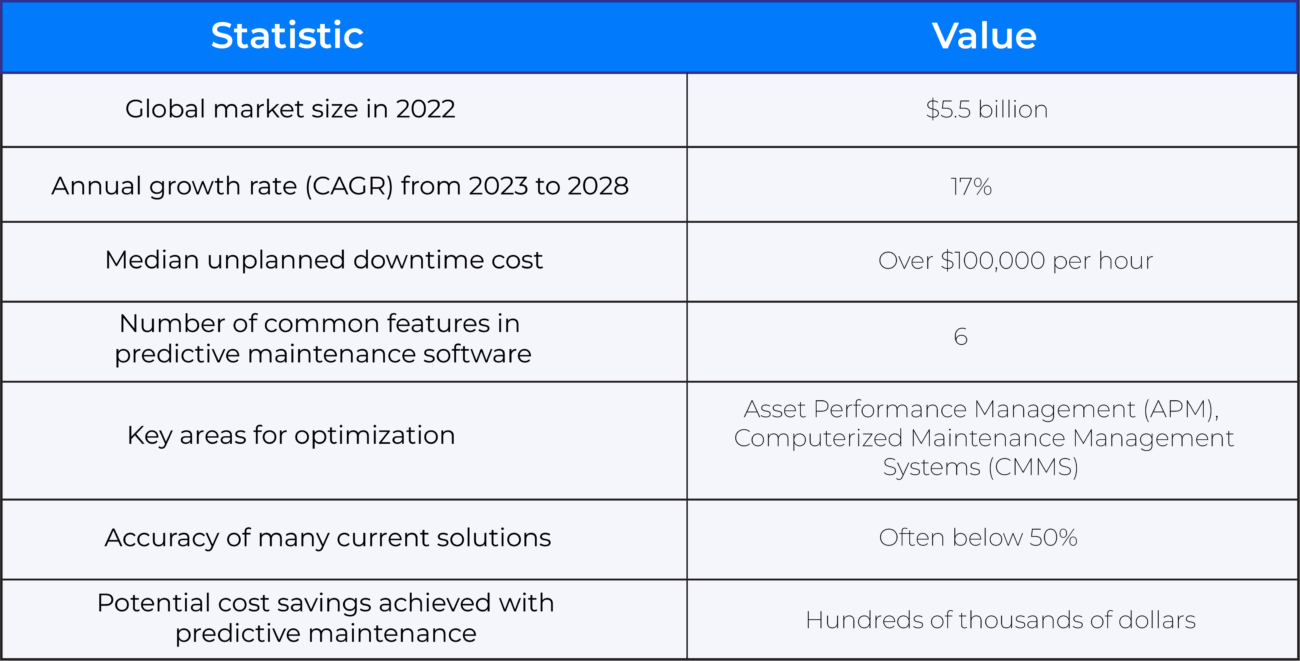

Did you know that the global predictive maintenance market surged to $5.5 billion in 2022? Impressive! Right? 11% growth from the previous year revealed by the latest Predictive Maintenance and Asset Performance Market Report 2023–2028.

This growth can be attributed to businesses worldwide recognizing predictive maintenance as a promising solution to reduce expenses incurred due to unexpected equipment failures. Moreover, this market is projected to maintain a robust Compound Annual Growth Rate (CAGR) of 17% until 2028.

These statistics underscore the increasing significance of accurately predicting failures of large assets to mitigate the staggering median unplanned downtime costs, which often exceed $100,000 per hour.

Predictive Maintenance Market: By the Numbers

Here are the 5 pivotal highlights, that shed light on the market’s evolution and opportunities.

- Market Valuation and Growth: – The predictive maintenance industry is growing rapidly and is expected to reach a valuation of $5.5 billion by 2022 – This indicates a surge in demand for solutions that can predict and prevent operational disruptions across various industries.

- Types of Predictive Maintenance: – Indirect failure prediction, anomaly detection, and remaining useful life (RUL) are three different types of predictive maintenance methods being used – Reflect the different approaches adopted to anticipate and prevent operational disruptions Predictive Maintenance

- Software Tools: – Predictive maintenance software tools usually share six common features, including data collection, analytics, and status visualization – These features highlight the technological advancements and functionalities shaping the predictive maintenance landscape Integration into

- Maintenance Workflow: – The seamless integration of predictive maintenance solutions into larger Asset Performance Management (APM) and Computerized Maintenance Management Systems (CMMS) signifies a pivotal shift toward more holistic and optimized maintenance strategies shift toward more holistic and optimized maintenance strategies.

- Success of Standalone Solutions: – Some predictive maintenance solutions specialize in specific industries or assets and have been successful in pioneering innovation and tailored solutions – These solutions have contributed significantly to the growth of the market, as they can bring in the difference and provide value to their clients.

Despite the promising outlook for predictive maintenance, lingering challenges persist, notably the inadequate accuracy of many solutions, often falling below 50%. This has posed considerable hurdles for maintenance organizations, eroding trust and impeding the seamless adoption of predictive maintenance technologies.

However, amidst these challenges, the potential for substantial cost savings and enhanced operational efficiency remains a compelling allure for businesses. The report highlighted that predictive maintenance solutions have been instrumental in saving companies hundreds of thousands of dollars, emphasizing the tangible benefits and Return on Investment (ROI) potential.

As decision-makers navigate this dynamic landscape, understanding the diverse predictive maintenance solution types, software features, and the potential for tailored, industry-specific offerings becomes imperative to make well-informed investment decisions for their assets. Whether you’re in manufacturing, Energy, or Healthcare, Qritrim can help you find the best solutions for your specific needs. Our industry-agnostic approach and focus on accuracy make us a trusted partner for businesses looking to unlock the full potential of predictive maintenance.

The fast-paced expansion and development of the predictive maintenance market highlight how important it is to improve the way businesses manage their assets, ensure sustainability, and maintain operational resilience. With the help of new technologies, customized solutions, and a focus on precision, predictive maintenance is driving significant changes and unlocking new possibilities for industries around the world.