Discover the True Potential of AI in Manufacturing

Introducing Artificial Domain Intelligence

What is Artificial Domain Intelligence?

Artificial Domain Intelligence (ADI) refers to the application of artificial intelligence (AI) technologies in the context of a specific domain or industry, such as manufacturing.

ADI goes beyond general-purpose AI applications and focuses on developing AI solutions tailored to the unique challenges, requirements, and opportunities within the manufacturing domain.

The Missing link of Traditional AI

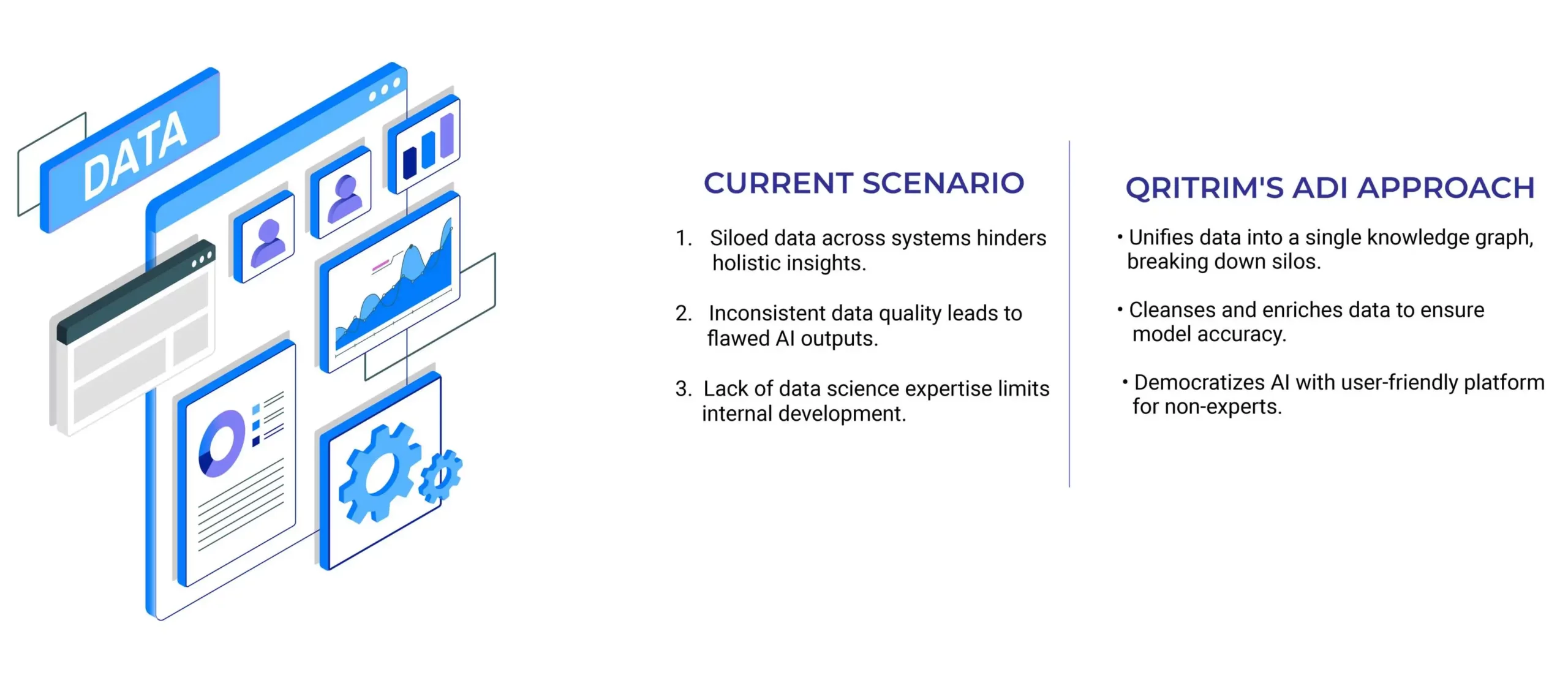

- Unstructured data overload: Modern businesses generate massive amounts of data from diverse sources, often in unstructured formats like documents, emails, sensor readings, and images. Extracting meaningful information from this data chaos can be daunting and time-consuming, hindering critical decision-making.

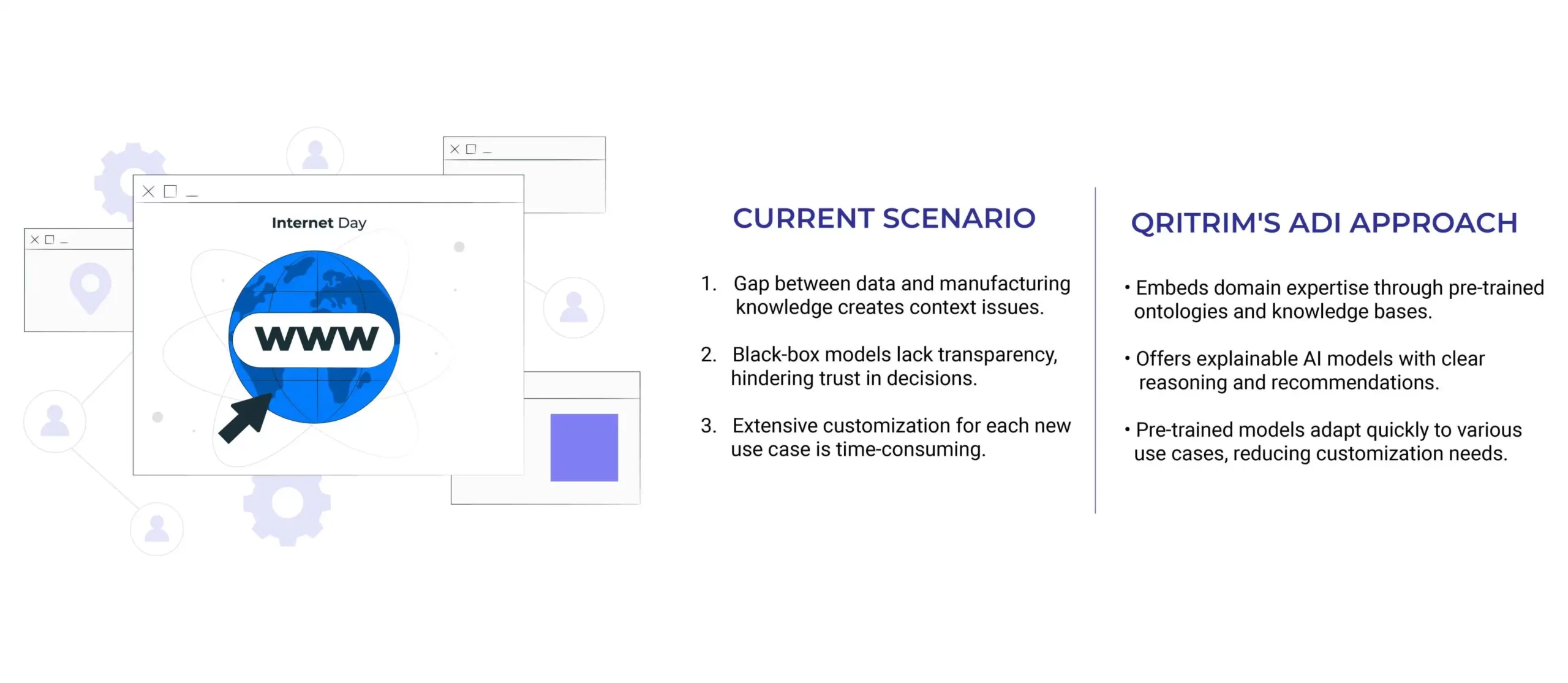

- Limited domain expertise in AI models: Traditional AI solutions often lack the deep understanding of specific industry knowledge and context required to generate truly valuable insights. This leads to generic results that may not address the unique needs and challenges of different sectors.

FROM TRADITIONAL AI TO ARTIFICIAL DOMAIN INTELLIGENCE

Creating a comprehensive knowledge base

Extracted data is organized into a structured knowledge base, readily accessible for analysis, decision-making, and further insights.

Ingest and structure

any type of data

Our AI powered Qi platform can handle virtually any data format (sensor data, production records, quality inspection data, maintenance logs, supply chain information, and more), automatically extracting key entities, relationships, and concepts.

Build domain

specific ontologies

We leverage industry knowledge and expertise to build customized ontologies, ensuring AI models have the necessary domain knowledge to interpret data accurately and in context.

Building Domain-Specific Ontologies

By combining domain expertise, advanced data analysis, and iterative development, Qritrim builds impactful domain-specific ontologies that empower AI models to deliver accurate, insightful, and context-aware results in specific industries.

Industry Expertise & Knowledge Acquisition:

Expert collaboration with domain experts (engineers, researchers, industry practitioners) to gather in-depth understanding of specific industry terminology, concepts, relationships, and processes.

Leverage your existing domain specific resources, standards, ontologies, and knowledge bases to save time and ensure alignment with established knowledge structures.

Data Analysis & Representation:

Data analysis to automatically extract relevant entities, relationships, and hierarchies.

Advanced algorithms identify patterns, trends, and hidden relationships within the data, enriching the ontology.

Ontology Development & Refinement:

Extracted knowledge is formalized using standardized ontology languages creating a structured representation of the domain.

Expert review to refine the ontology, ensuring accuracy, completeness, and alignment with industry standards and real-world practices.

Integration & Deployment:

Created ontology is integrated with our AI models fusing the necessary domain knowledge to accurately interpret and analyze data.

Model feedback utilized for Continuous Learning to iteratively refine and improve the ontology over time, ensuring its ongoing relevance, value and scale.

Qritrim’s Approach To Current AI Challenges

Few Practical Applications Of Adi In Manufacturing

Qritrim is a trusted partner in harnessing the strategic and practical potential of ADI (Artificial Intelligence and Digital Intelligence). With their extensive expertise and experience in AI technologies We're here to guide your journey toward industry transformation and innovation.

Predictive Analytics and Maintenance:

AI algorithms analyze historical data and real-time sensor data to predict equipment failures and maintenance needs to improve overall productivity and reduce costs.

- Minimize unplanned downtime

- Optimize maintenance schedules

- Extend the lifespan of equipment

Process Optimization and Automation:

AI that optimizes production schedules, resource allocation, and workflow efficiency.

- Streamline repetitive tasks & reduce human error

- Improve throughput for higher productivity and operational efficiency.

Quality Control and Assurance:

Enhance quality control and assurance in manufacturing by analyzing production data to detect defects, anomalies, and quality issues in real-time.

- Improve product quality

- Reduce scrap and rework

- Ensure compliance with quality standards and regulatory requirements.

Supply Chain Optimization:

Optimize the manufacturing supply chain by leveraging AI algorithms to analyze demand forecasts, inventory levels, supplier performance, and logistics data.

- Reduce lead times

- Minimize inventory costs

- Improve overall supply chain efficiency

- Quickly adapt to changing customer demands and market fluctuations.

Empowering Businesses to Stay Competitive and Innovative

Unlock actionable insights from data that traditional

methods lack.

Reduced development costs with no-code/low-code, drag & drop interface.

Adapt quickly to diverse use cases and evolving manufacturing environments.

Domain-specific understanding ensures AI models interpret data more accurately.

Faster time to value as domain knowledge accelerates AI implementation and delivers ROI.