The manufacturing industry has undergone a significant shift with the advent of Industry 4.0 which is more than just a buzzword. It signifies a fundamental change involving innovative technologies such as artificial intelligence, data analysis, and interconnected systems. These components collectively redefine factory operations and interactions, marking a new era in global manufacturing.

Industry 4.0 Essentials: Redefining Manufacturing Practices

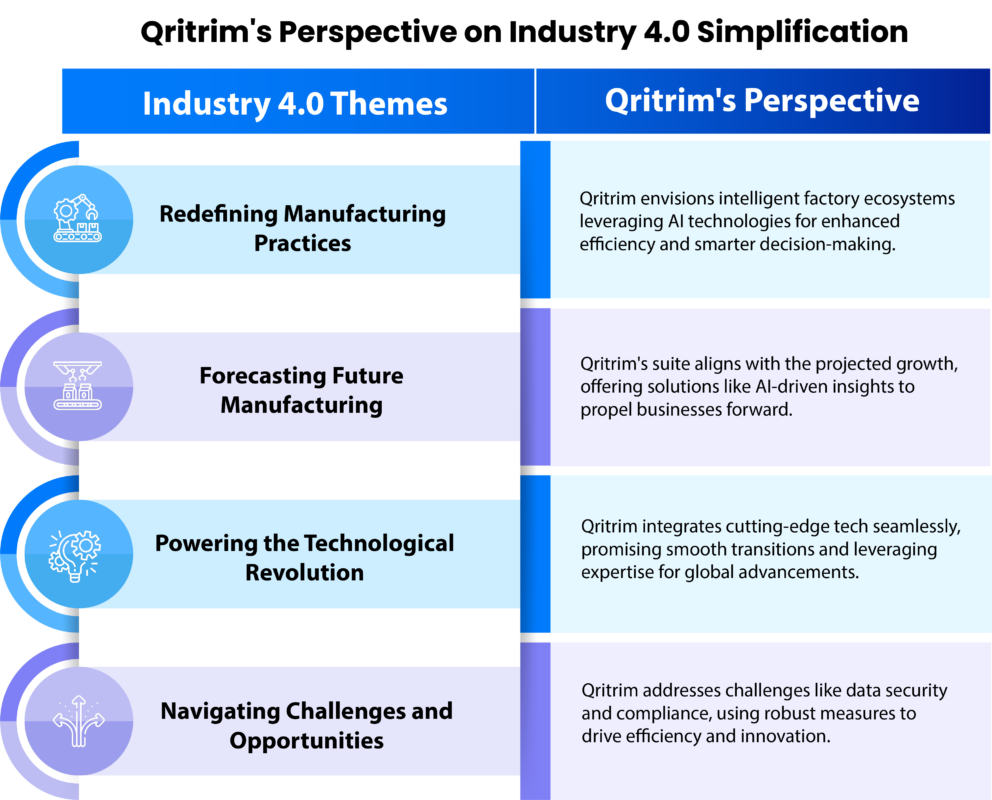

Industry 4.0 is a transformational change that redefines manufacturing practices. It envisions factories as intelligent ecosystems where machines and systems are seamlessly connected, facilitating communication. This revolution relies on advanced technologies such as AI, big data analytics, and robotics to optimize operations. The primary goal is to enhance efficiency, foster smarter decision-making, and revolutionize manufacturing practices to achieve significant advancements.

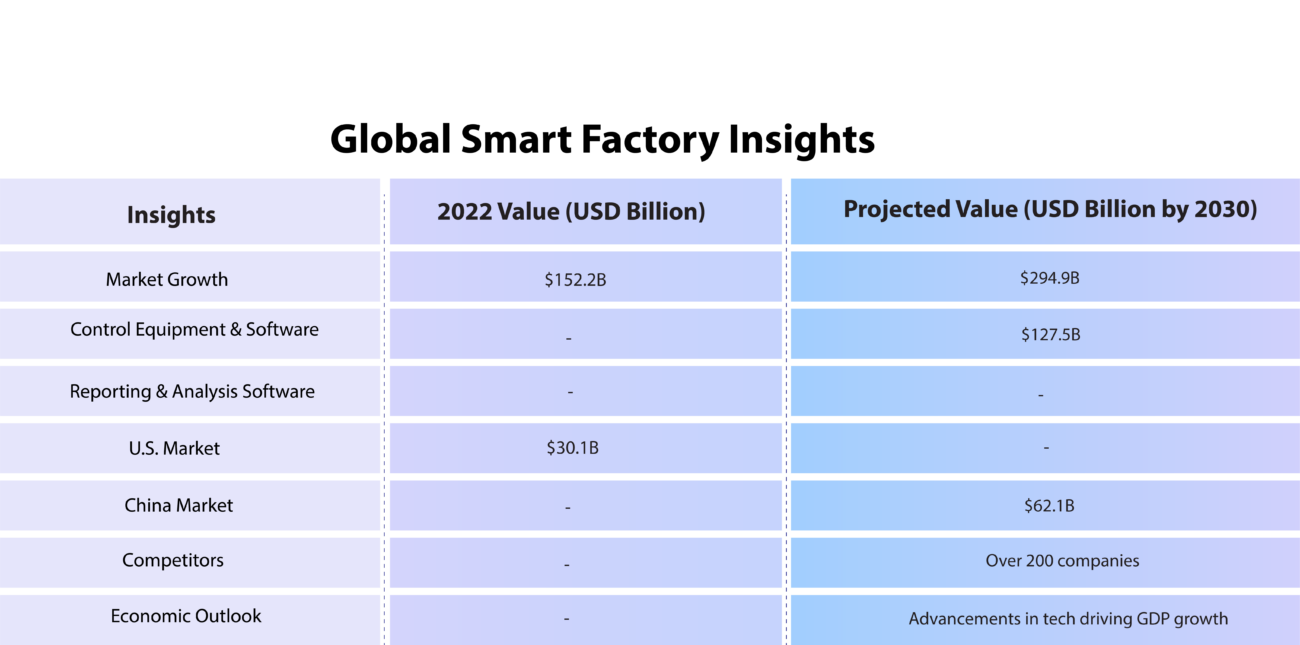

Global Smart Factory Insights: Forecasting Future Manufacturing

Insights from the Global Smart Factory Market provide valuable glimpses into the future of manufacturing. Recent analyses by industry experts suggest substantial growth potential, with the market value potentially doubling by the end of the decade. These projections explore critical aspects such as market segments, geographical markets, major competitors, and the overall economic landscape, offering a clear vision of the transformative potential ushered in by Industry 4.0.

These figures illustrate the Smart Factory Market’s growth trajectory, reflecting an impressive Compound Annual Growth Rate (CAGR) of around 8.6%. The landscape witnesses a flourishing competitive scene, hosting over 200 notable companies, depicting the transformative potential of Industry 4.0 within the manufacturing sector.

Technological Advancements Driving Industry 4.0: Powering the Revolution

At the core of Industry 4.0 lie groundbreaking technological advancements encompassing connectivity, data analytics, and human-machine interaction. The focus is on creating not just efficient but intelligent factories. These advancements aim to streamline manufacturing processes, enhancing agility and productivity across industries.

Digitalization of the Supply Chain: Transforming Operations

Industry 4.0 introduces a significant shift—the digitalization of supply chains. Traditional methods are giving way to digital integration, enabling seamless data flow across operations. Cloud-based platforms facilitate global collaboration, empowering swift decision-making and real-time enhancements, ensuring swift adaptation to market dynamics regardless of geographical constraints.

Cross-Border Collaboration and Global Competition: Embracing Innovation

Industry 4.0 fosters global collaboration through open innovation ecosystems. Diverse expertise converges, ranging from startups to established institutions, accelerating innovation. This collaboration transcends borders, fostering cutting-edge solutions. The expanded global competition emphasizes the importance of embracing technological advancements to lead in an interconnected world.

Industry 4.0 Challenges and Opportunities

While promising immense benefits, Industry 4.0 poses challenges such as data security, compliance, and cultural differences. Yet, addressing these obstacles with adaptability and collaboration unlocks Industry 4.0’s potential, ensuring enhanced productivity and competitive advantages.

Industry 4.0 Unveiled: Qritrim’s Role

Industry 4.0 isn’t just about machines; it’s about creating smarter, connected systems that make global work smarter. This significant change, powered by new tech and ideas, promises more innovation and teamwork, pushing factories to reach new levels.

How Qritrim is a catalyst for the Smart Factory Era?

Qritrim stands by your side, making the journey through these complexities a breeze. Our goal? To simplify modernization and bring you concrete results that make a difference. We help with tricky things like keeping data safe while making work better and smarter. Qritrim’s here to make things easier for industries moving ahead.

Industry 4.0 Themes – Qritrim’s Perspective:

Qritrim stands by your side, making the journey through these complexities a breeze. Our goal? To simplify modernization and bring you concrete results that make a difference. We help with tricky things like keeping data safe while making work better and smarter. Qritrim’s here to make things easier for industries moving ahead.

Our Expertise & Solutions:

- ? AI-Powered Solutions: Automate tasks and fine-tune workflows with cutting-edge AI tech.

- ? Integrated Platform: Seamlessly blend our platform with your systems for a smooth transition.

- ? Industry-Specific Mastery: Tailor-fit solutions that match your unique industry needs.

- ? Global Support: Providing global expertise right to your doorstep.

Qritrim’s Impact:

- ? Increased Efficiency: Less downtime, more output – like a well-oiled machine!

- ? Smarter Decision-Making: Optimize production and spot potential issues with data-driven insights.

- ? Enhanced Flexibility: Stay ahead of market shifts with agile systems.

- ? Improved Quality: Consistent top-notch product quality through real-time data insights.

Embracing Industry 4.0 with Qritrim stands as your guide in this dynamic landscape, offering AI-powered solutions that redefine how industries operate.

Key Takeaways:

- Simplified Innovation: Qritrim ensures businesses thrive in the smart factory revolution by simplifying complex tech.

- Aligned with Growth: Our solutions match forecasted growth, driving businesses towards a tech-powered future.

- Security and Efficiency: Tackling challenges like data security, making operations safer while boosting productivity.

Take the Next Step with Us:

Ready to embrace the future of manufacturing? Explore how Qritrim can propel your business into Industry 4.0. Reach out today for a consultation and unlock the potential of smarter, connected systems in your industry.

Let’s transform together with Qritrim, making Industry 4.0 innovation simple and accessible for your business.

FAQ’s

How Industry 4.0 is Changing Manufacturing?

Industry 4.0 changes manufacturing by linking machines, allowing them to communicate and operate together intelligently. For instance, sensors in a factory can communicate with machines to self-adjust settings for optimal production.

Benefits of Implementing a Smart Factory?

Smart factories elevate productivity by automating tasks. For instance, robots working alongside humans can reduce assembly time, enhance quality, and minimize errors in manufacturing processes.

Challenges of Implementing Industry 4.0?

Implementing Industry 4.0 faces hurdles like initial costs. For example, integrating new technologies and training employees to use them efficiently can be a significant challenge for businesses.

How Qritrim Can Help You Implement Smart Factory Solutions?

Qritrim offers tailored support to smoothly integrate smart factory solutions. For example, they assist in incorporating IoT devices seamlessly into existing factory systems, ensuring a hassle-free transition.

How to Improve Data Security in Your Smart Factory?

Qritrim ensures smart factories have robust security measures in place. For instance, they employ encryption methods similar to those used in online banking to protect sensitive data from cyber threats.

The Future of Manufacturing with Industry 4.0?

The future of Industry 4.0 involves advanced automation. For instance, self-diagnosing machines in a factory can predict maintenance needs, reducing downtime significantly.

How Qritrim Can Help You Increase Efficiency in Your Smart Factory?

Qritrim enhances smart factory efficiency using AI algorithms. For example, implementing AI-driven predictive maintenance minimizes equipment breakdowns and optimizes production.

How Qritrim Can Help You Improve Decision-Making in Your Smart Factory?

Qritrim provides data-driven insights for informed decision-making. For example, real-time analytics dashboards can help factory managers make quick adjustments to production schedules based on demand fluctuations.

How Qritrim Can Help You Increase the Flexibility of Your Smart Factory?

Qritrim tailor’s smart factory solutions for adaptability. For instance, flexible automation systems allow manufacturers to easily switch production lines to meet varying customer demands swiftly.